| Porting guide 429/460 pass car castings pictorial |

| pg. 2 |

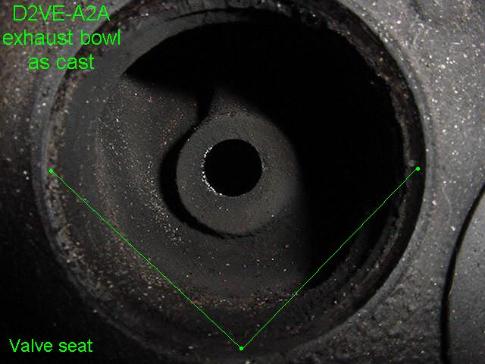

| The greater distance from valve seat to the short turn radius in the '72 and prior castings allows the porter to better aim the flow cone under the valve head via the bowl blend. When finished the bowl diameter should be about .100" to .125" smaller than the seats diameter. A 1.65" valve needs about a 1.380" bowl dia. and a 1.72" valve needs a 1.475" bowl dia. The sides of the bowl need to be parallel with the valve stem centerline The back should slope toward the valve stem or guide. The back of the bowl should be conservatively blended to avoid flow seperation at the back of the bowl. |

| Begin the bowl blend by laying back the machined ridges that are above the valve seat. Do not open the bowl up as large as the seat diameter.Reduced bowl diameter will act as a venturi and acceterate the flow into the transition from bowl to main port passage. Bowl diameter should be 83% of valve head diameter or 87% of valve "seat" diameter. Make the bowl too large and flow seperation will occur at the seat and hurt flow. You want to aim the flow toward the port roof. Allow .375" before beginning to lay back the short turn.This is possible with the D3, D4, and D8 castings but isn't possible with the C8, C9, and D0VE-A&C casting numbers. Get as close as you can with the older castings Bowl diameter should be 1.475" for the CJ exhaust valve. Bowl diameter should be 1.380" for the stock 1.65" valve. Do not exceed these sizes updated 11-03 |

| See page 3 for more pics. The left, right and longside views are shown. |

| Do not begin to roll the short turn right off the valve seat. This will tear one side out of the flow cone under the valve head and hurt flow. This is critical !!! |

| Step 2 |